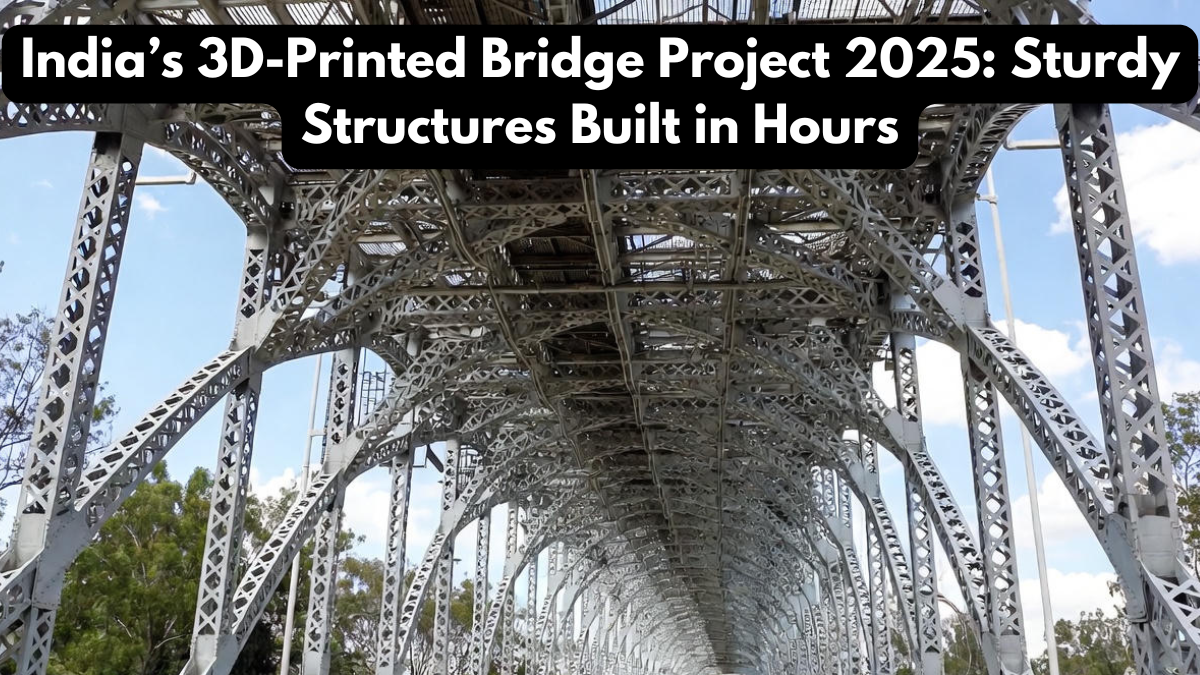

Infrastructure development in India has traditionally been a time-consuming and resource-intensive process, often delayed by labor shortages, high costs, and complex logistics. By 2025, 3D Printed Bridge India projects are redefining this reality by introducing rapid, automated construction methods that can build durable bridges in a matter of hours. Powered by next-generation Construction tech, these projects demonstrate how innovation can accelerate infrastructure growth without compromising safety or quality.

As India continues to expand its road and transport networks, especially in rural and semi-urban regions, the need for faster and more efficient construction methods has never been greater. 3D Printed Bridge India represents a strategic shift toward smart infrastructure, where Construction tech enables precision, sustainability, and speed at an unprecedented scale.

How 3D Printed Bridge India and Construction Tech Work

The core of 3D Printed Bridge India lies in large-scale additive manufacturing systems specifically designed for construction. These systems use robotic arms or gantry-based printers that deposit layers of specialized concrete mixtures according to digital blueprints. Advanced Construction tech ensures that each layer bonds perfectly, creating structures with high strength and consistency.

Before printing begins, engineers design the bridge using computer-aided models that account for load capacity, environmental conditions, and material efficiency. 3D Printed Bridge India projects rely on Construction tech innovations such as fiber-reinforced concrete, real-time quality monitoring, and automated curing processes. This integration allows bridges to be printed on-site or in modular sections that are later assembled, drastically reducing construction timelines.

Key Benefits of 3D Printed Bridge India Projects

The adoption of 3D Printed Bridge India brings transformative benefits to infrastructure development. With the support of Construction tech, these bridges address long-standing challenges faced by traditional construction methods.

Key benefits include:

- Drastically reduced construction time

- Lower labor dependency and improved safety

- Cost savings through material efficiency

- High structural precision enabled by Construction tech

- Reduced environmental impact

These advantages make 3D Printed Bridge India an attractive solution for rapid infrastructure expansion across diverse terrains.

Comparison of Traditional Bridge Construction vs 3D Printed Bridge India

The table below compares conventional bridge construction with 3D Printed Bridge India, highlighting the role of advanced Construction tech.

| Aspect | Traditional Bridge Construction | 3D Printed Bridge India |

|---|---|---|

| Construction Time | Months or years | Hours or days |

| Labor Requirement | High | Low |

| Material Waste | Significant | Minimal |

| Design Flexibility | Limited | High via Construction tech |

| Cost Efficiency | Moderate | High |

This comparison clearly shows how 3D Printed Bridge India streamlines infrastructure delivery through automation and precision.

Applications in Rural Connectivity and Urban Infrastructure

One of the most impactful uses of 3D Printed Bridge India is in rural connectivity. Many villages remain isolated due to damaged or missing bridges over small rivers and canals. With portable printers and modular designs, Construction tech enables authorities to deploy bridges quickly, restoring access to schools, markets, and healthcare facilities.

In urban environments, 3D Printed Bridge India projects support pedestrian bridges, cycle paths, and flyover components. The flexibility of Construction tech allows for customized designs that blend with existing infrastructure while meeting strict safety standards. Rapid deployment also minimizes traffic disruptions, a major concern in densely populated cities.

Sustainability and Material Innovation in 3D Printed Bridges

Sustainability is a key advantage of 3D Printed Bridge India initiatives. By using precisely calculated material quantities, waste is significantly reduced. Many projects incorporate recycled aggregates and low-carbon cement alternatives, further enhancing the environmental benefits of Construction tech.

Energy consumption is also optimized. Automated printing systems operate efficiently and reduce the need for repeated transport of materials and labor. Over time, 3D Printed Bridge India contributes to greener infrastructure development while maintaining long-term durability and performance.

Challenges, Standards, and Regulatory Readiness

Despite its promise, 3D Printed Bridge India faces challenges related to standardization, certification, and public acceptance. Infrastructure authorities must ensure that printed bridges meet national safety codes and long-term durability requirements. Construction tech standards are evolving, and regulatory bodies are working to update guidelines accordingly.

Training engineers and inspectors to work with 3D Printed Bridge India systems is another priority. As expertise grows and pilot projects demonstrate success, confidence in Construction tech will continue to increase, paving the way for wider adoption.

Future Outlook and Conclusion

By 2025, 3D Printed Bridge India is expected to move from pilot projects to mainstream infrastructure solutions. As printer capabilities improve and materials become more advanced, bridges will be built faster, stronger, and more sustainably. Integration with digital twins and smart monitoring systems will further enhance the value of Construction tech.

In conclusion, 3D Printed Bridge India represents a major leap forward in how infrastructure is designed and built. Through innovative Construction tech, India can address connectivity challenges, reduce construction delays, and create resilient structures efficiently. This approach not only modernizes bridge construction but also sets a global benchmark for rapid, technology-driven infrastructure development.

FAQs

What is 3D Printed Bridge India?

3D Printed Bridge India refers to infrastructure projects where bridges are built using large-scale 3D printing and advanced Construction tech.

How strong are 3D-printed bridges?

They are engineered to meet or exceed safety standards using reinforced materials and precise Construction tech controls.

How long does it take to build a 3D-printed bridge?

Many 3D Printed Bridge India projects can be completed in hours or days instead of months.

Are 3D-printed bridges suitable for rural areas?

Yes, they are ideal for rural connectivity due to rapid deployment and reduced resource needs enabled by Construction tech.

Why is 3D Printed Bridge India important for the future?

It accelerates infrastructure development, reduces costs, and showcases how Construction tech can transform public works.

Click here to know more.